Remotely Operated Cable Laying System

Extend the reach of your cabled observatory

The Remotely Operated Cable Laying System (ROCLS) answers one of the most challenging problems encountered in the installation of cabled ocean observatories: the connection of instruments and secondary nodes located kilometers away from the main observatory nodes. ROCLS is a unique, simple, and robust system that enables the installation of long extension cables weighing thousands of pounds in situations that would be very costly, extremely difficult or impossible to manage from a cable ship.

Components

A brief system overview

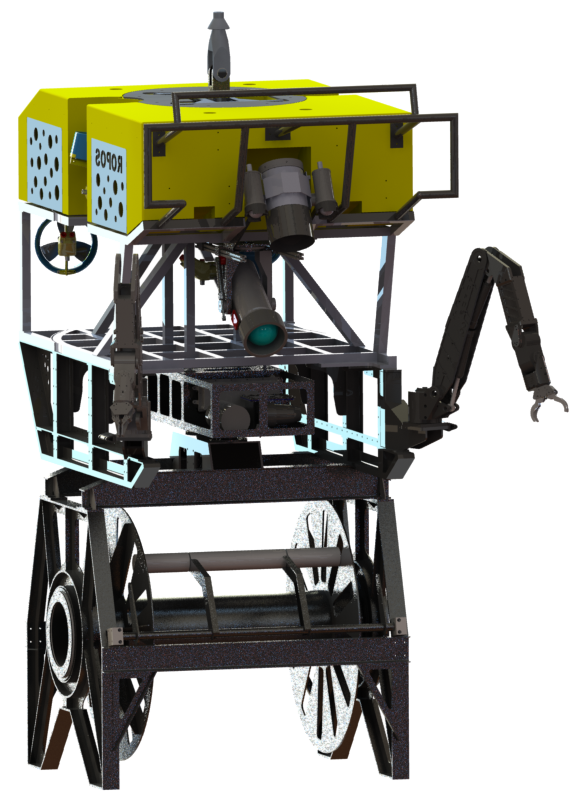

The ROCLS system consists of two major components: the toolskid and the drum frame. The toolskid is attached to the ROPOS through-frame lift system and contains all electrical and hydraulic components required to couple/decouple ROPOS to the drum frame and drive the drum components. The drum frame supports the cable drum while it is on deck, on the seafloor or in position under the vehicle.

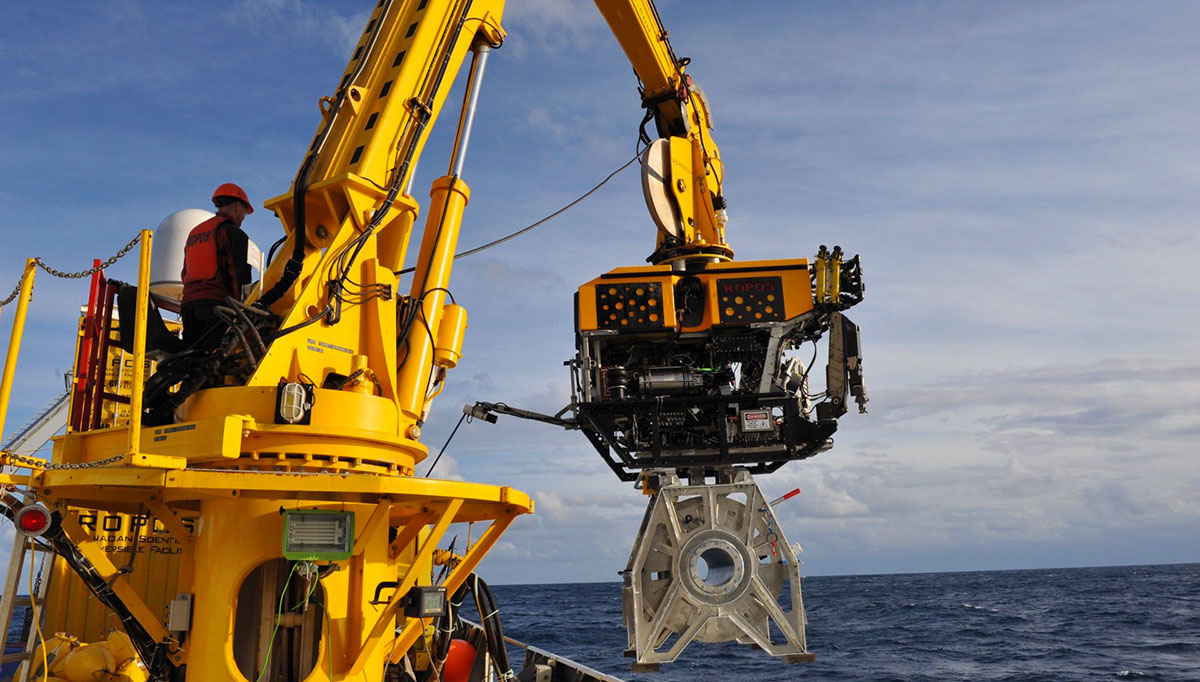

ROPOS on ROCLS

ROPOS latched to the ROCLS drum frame using the toolskid mounted on the through-frame lift. For ROCLS operations, ROPOS is configured with several monitoring cameras, including a remotely controlled boom camera, that monitor all ROCLS operations.

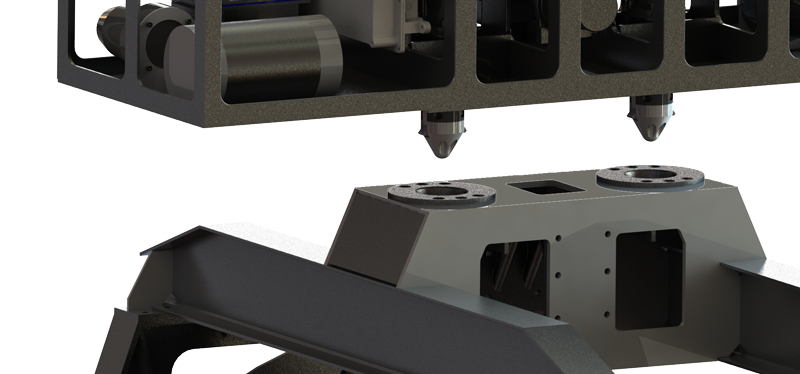

Toolskid

The ROCLS toolskid shown attached to the ROPOS through-frame lift. The 4000 lb through-frame lift uses titanium rods that link the toolskid directly to ROPOS' armored umbilical allowing ROPOS to lift the fully loaded ROCLS drum frame.

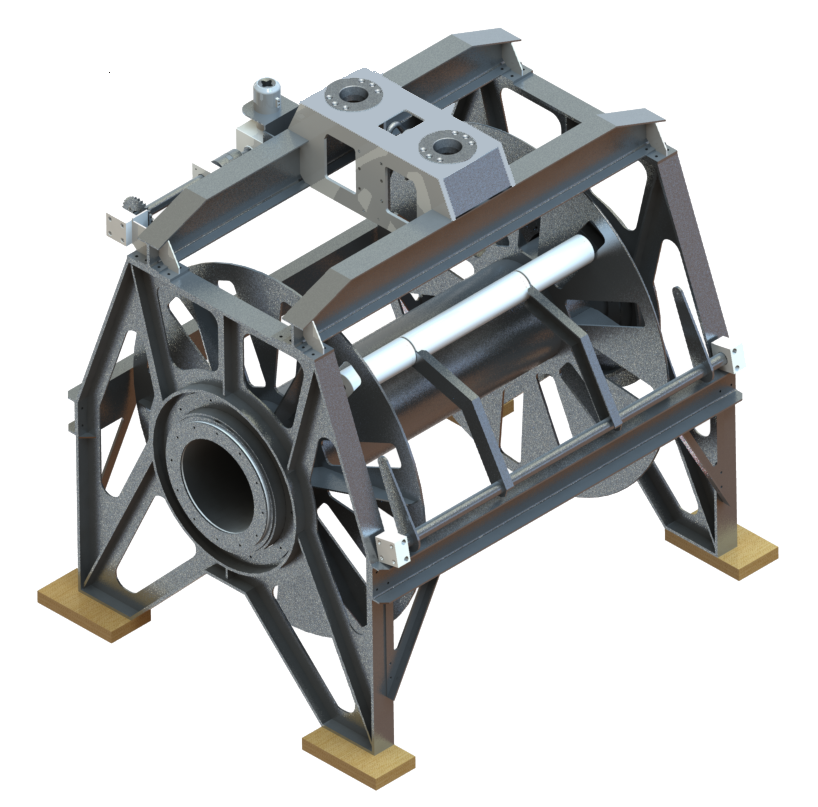

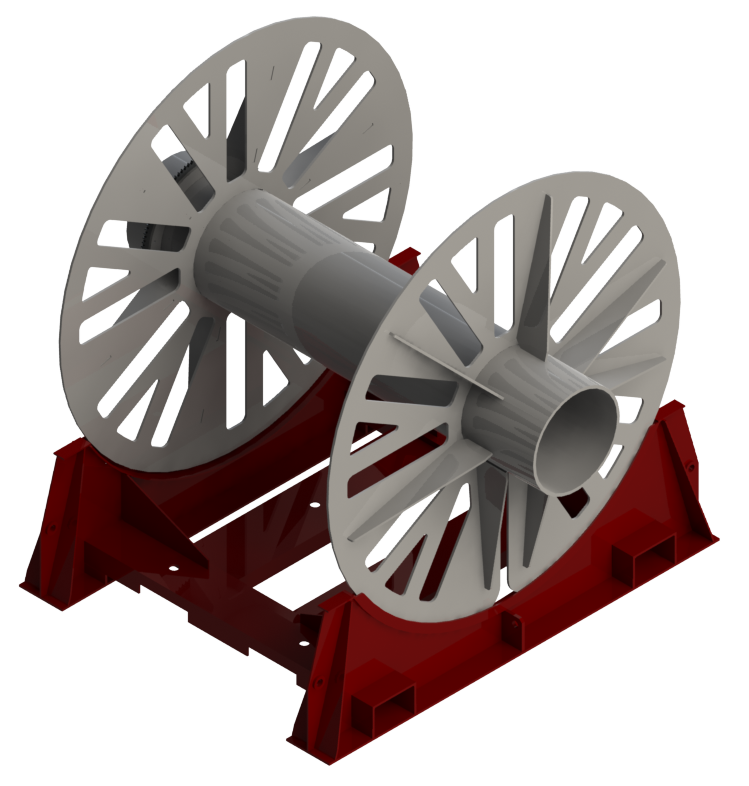

Drum frame

The drum frame is fitted with CSSF's observatory latching interface for quick coupling and decoupling. Once coupled to ROPOS, a proportionally controlled drive motor is engaged to payout the cable in a controlled manner.

Latches

Do more on the bottom

With the latches on the toolskid, ROPOS can be coupled and decoupled from the ROCLS drum frame while on the seafloor. This allows ROPOS to free swim and connect the cable ends to the instrument packages and to the node as well as to perform other operations. Once these operations are completed, ROPOS can then re-couple to the ROCLS drum frame and continue laying cable, or recover the empty drum to the surface.

Drum and Cradle

More is better

Efficient use of ship time has been a constant driver in the ROCLS design and engineering process. With the drum and cradle system, we can carry and deploy over a dozen extension cables without resupply. Drums are easily removed and reinstalled in the ROCLS frame, allowing multiple drums to be pre-spooled on shore, or re-spooled offshore. Since we have two ROCLS drum frames, a cable can be fitted on deck while another cable is being laid subsea.

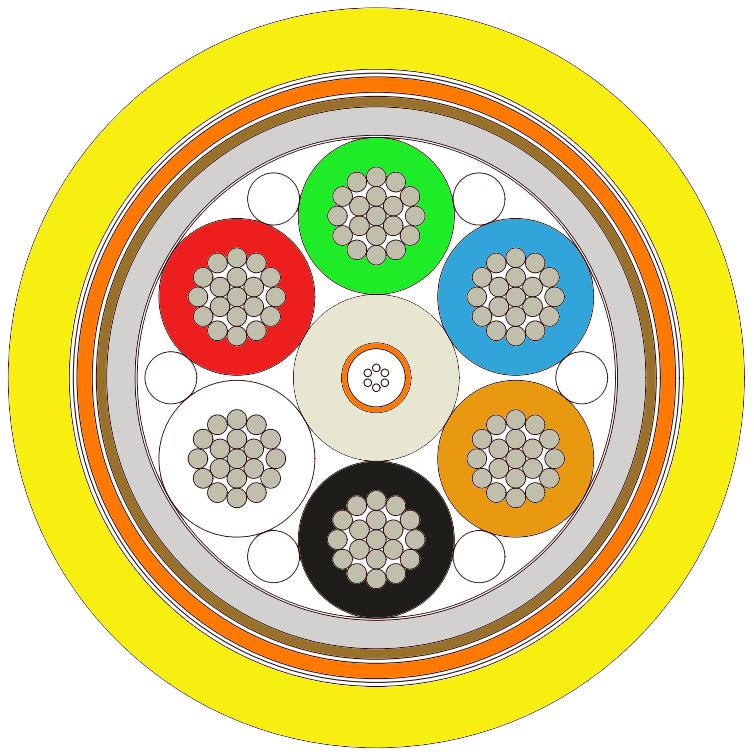

Cables

The power and data you need

The need to lay long synthetic cables conducting high voltage was one of the driving factors behind the creation of ROCLS. These are cables with a Kevlar strength member and large conductors. The ROCLS drum was designed to carry roughly 8000 meters of 14 mm O.D. polyurethane jacketed electrical/optical cable or 5750 meters of 18 mm cable of similar internal construction. ROCLS has already accommodated a wide variety of cables types in lengths from 300 m to over 20 km.